Fascination About Premier Aluminum Llc

Table of ContentsThe Premier Aluminum Llc Statements5 Easy Facts About Premier Aluminum Llc ShownSee This Report about Premier Aluminum LlcThe Main Principles Of Premier Aluminum Llc

(https://www.pubpub.org/user/gary-martin)Traditionally, a buyer's key obligation was to discover competent and responsive vendors. Sometimes, buyers assumed that any type of provider willing to contractually meet the purchase need was qualified. Nonetheless, making use of inexpensive and unqualified suppliers can create quality concerns, and lost time and money in the long run. To help you via the procedure, here are some points to take into consideration when picking the appropriate metal casting distributor.

For instance, a company that only utilizes the financial investment spreading process will try to market you on why that process is best for your application. However what if making use of the sand spreading procedure is best for you and your requirements? Instead, search for a supplier that offers a series of casting procedures so the most effective option for YOU is picked

If dealing with a single resource for every one of your casting needs is vital to you, the distributor requires to be varied in its capacities. When integrated with various other integrated abilities, this can help streamline and press the supply base. When picking the right spreading vendor, cautious factor to consider should be given to top quality, solution, and price.

Things about Premier Aluminum Llc

Buyers increasingly select casting vendors who have machining abilities. This can avoid conflict if defects are found throughout machining. If a 3rd event is machining, it may cause "finger-pointing" about that is at mistake. Is it a spreading concern or a Source machining issue? If the spreading vendor finds a problem during machining, the trouble is dealt with quicker with no disagreement over whose mistake it is.

What do you need from your spreading distributor? Are you looking for a person to simply deliver a steel element to your front door or do you require extra?

Some shops are restricted or specialized. Make sure the vendor can meet all your material or alloy demands to get rid of the requirement for numerous suppliers.

Not known Facts About Premier Aluminum Llc

Research study the provider's web site. Talk to a sales associate or business associate.

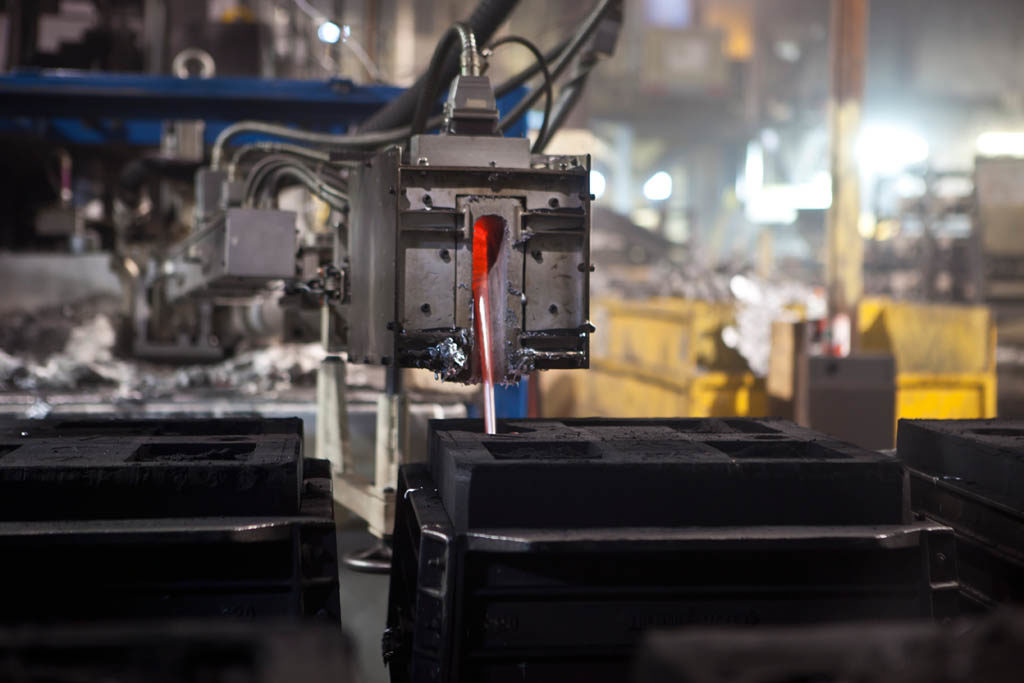

Light weight aluminum is additionally lightweight and has great corrosion resistance, making it perfect for applications where weight and sturdiness are essential variables. In addition, aluminum casting is a cost-effective approach of production, as it needs much less power and sources than various other approaches. Iron casting, on the various other hand, includes pouring molten iron into a mold to produce a preferred shape.

The Greatest Guide To Premier Aluminum Llc

Iron casting is additionally able to hold up against high temperatures, making it appropriate for use in applications such as engine parts and industrial equipment. Iron spreading can be much more costly than aluminum casting due to the higher cost of raw products and the energy called for to thaw the iron. When determining in between light weight aluminum casting and iron spreading, it is essential to consider the certain demands of the application.

In verdict, both light weight aluminum casting and iron spreading have their very own distinct benefits and downsides. There are three sub-processes that drop under the classification of die spreading: gravity die casting (or irreversible mold spreading), low-pressure die casting and high-pressure die casting. To obtain to the finished item, there are three key alloys utilized as die spreading material to pick from: zinc, aluminum and magnesium.